Page Content

Kaizen is a Japanese term meaning "continuous improvement, "It is a proactive methodology for improving performance at all organizational levels. This methodology is based on using logical methods without allocating new resources to enhance productivity within the organization. This concept aims to make the workplace more efficient and effective through:

• Creating a teamwork environment

• Improving daily procedures and operations

• Ensuring collective employee participation

• Increasing job satisfaction

• Enhancing job security

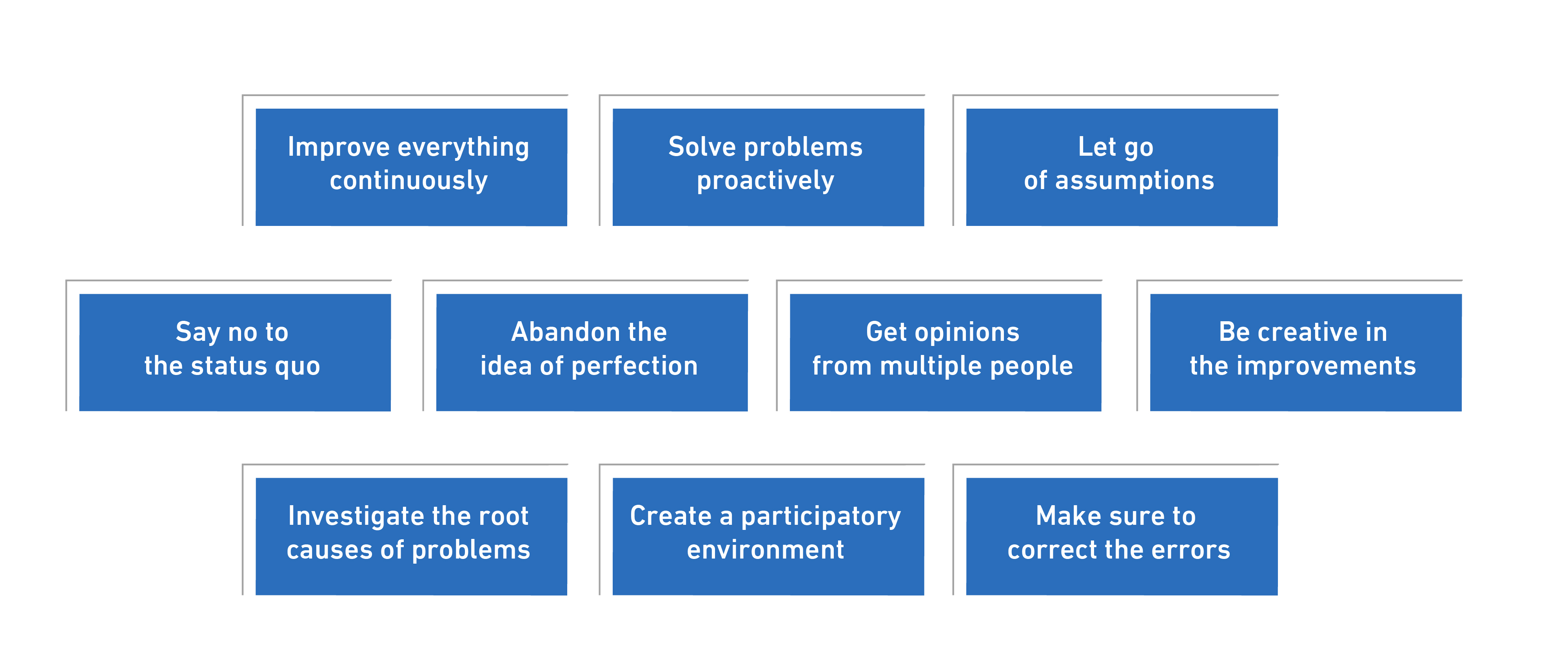

Kaizen’s Principles

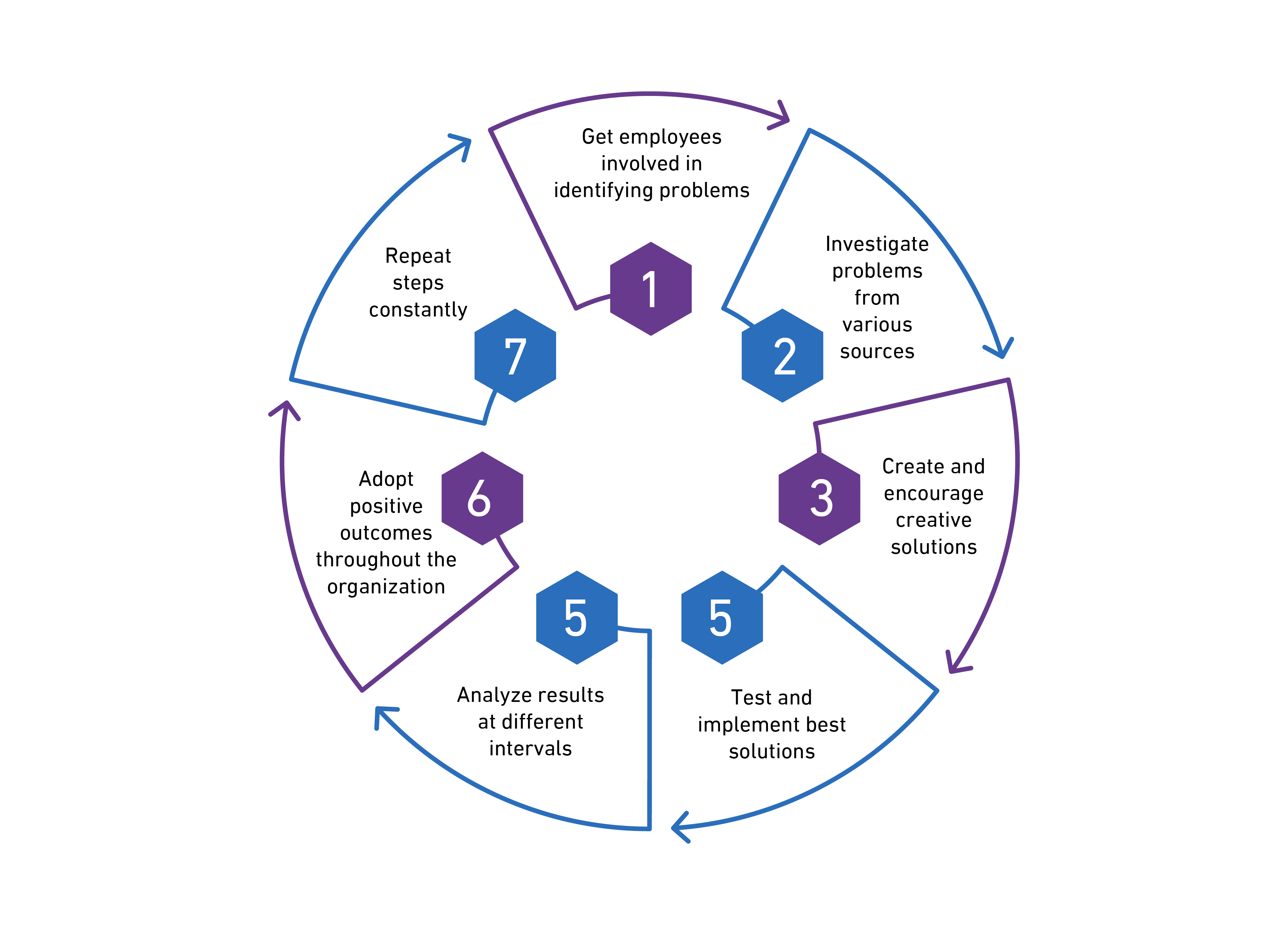

Kaizen's Cycle

Kaizen methodology can be implemented in a seven-step cycle to create an environment based on continuous improvement.

A journey of a thousand miles begins with a single step

One of the secrets of Kaizen success is its focus on minor improvements to achieve success in the long run. These improvements, which do not require much time, often prove effective. Toyota employs Kaizen philosophy as one of its central values. It also applies the 5S approach throughout the company to implement improvement and development efficiently and effectively.

The 5S Approach:

• Sort: Sorting and classifying worksheets

• Straighten: Items should be found within 30 seconds

• Shine: Clean workplace to create a comfortable working environment

• Standardize: Create a set of standards for sorting, straightening, and shining

• Sustain: Practicing previous steps on regular